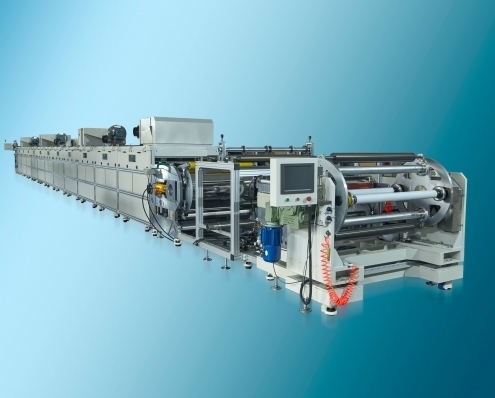

DL-LYJ-22GD1000 The steel belt casting machine is suitable for the highest production requirements. Advanced servo alignment correction, servo tension control, high-speed steel belt, efficient drying system, and continuous operation coil replacement mechanism make it highly suitable for producing tapes ranging from 20 to 1200 micrometers. The entire process, from feeding to collecting the green bodies, is highly automated.

DL-LYJ-22GD1000 The steel belt casting machine is suitable for the highest production requirements. Advanced servo alignment correction, servo tension control, high-speed steel belt, efficient drying system, and continuous operation coil replacement mechanism make it highly suitable for producing tapes ranging from 20 to 1200 micrometers. The entire process, from feeding to collecting the green bodies, is highly automated.

Equipment model Equipment Specifications Equipment orientation Steel belt size Steel belt thickness Casting width Casting method Casting green bodies accuracy Casting speed

Discharge height Hot air drying temperature and humidity Heating method Automatic feeding system Operating Voltage Maximum power | DL-LYJ-22GD1000 28796*1700*2400MM (L*W*H) Casting machine head is on the left 1000mm*51000mm 1.0mm 900mm extrusion casting ±(1um+5%material thickness) 0.1-20 (m/min) not less than 15m/min on stable operation 450um RT-150℃ Electric hot air circulation Feed pump 380V 50/60HZ 200KW |

Equipment usage: The purpose of this equipment is to extrude and dry the well-mixed slurry into the desired film tape. The equipment primarily consists of a feeding tank, casting head, steel belt transmission mechanism, drying furnace, steel belt alignment mechanism, film tape peeling and cutting, and winding sections. The equipment's structural design is rational, effectively controlling the thickness, density, drying level, and uniformity of the film tape, achieving safety, reliability, high precision, and efficiency. | |