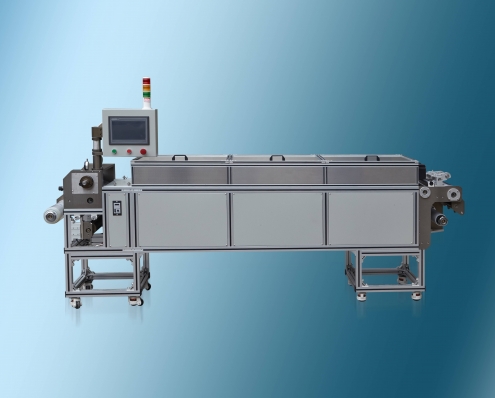

DL-LYJ-2QE240 The experimental casting machine operates by allowing the mixed slurry to flow into a trough above a baseband (PET), where it forms a green bodies through the relative movement between the baseband and a comma-shaped scraper. The thickness of the green bodies is controlled by the scraper (with an adjustable accuracy of up to 0.001mm).

The green bodies, along with the baseband, is then conveyed into a drying chamber, where the solvent evaporates. An organic binder forms a network structure between ceramic particles, resulting in green bodies with a certain level of strength and flexibility. Once dried, the green bodies are separated, undergo electrostatic removal, and then are collected as rolled tape.

This equipment is characterized by high precision, high speed, stable performance, environmental friendliness, and energy efficiency.

DL-LYJ-2QE240 The experimental casting machine operates by allowing the mixed slurry to flow into a trough above a baseband (PET), where it forms a green bodies through the relative movement between the baseband and a comma-shaped scraper. The thickness of the green bodies is controlled by the scraper (with an adjustable accuracy of up to 0.001mm).

The green bodies, along with the baseband, is then conveyed into a drying chamber, where the solvent evaporates. An organic binder forms a network structure between ceramic particles, resulting in green bodies with a certain level of strength and flexibility. Once dried, the green bodies are separated, undergo electrostatic removal, and then are collected as rolled tape.

This equipment is characterized by high precision, high speed, stable performance, environmental friendliness, and energy efficiency.

Equipment model Equipment boundary dimensions Solvent Baseband Baseband width Casting width Tool adjustment accuracy Thickness accuracy Scraper accuracy Scraper Casting speed Casting thickness μ(WET) Scraper height μ(WET) Viscosity mpa.s Effective drying length Temperature control Temperature control Peeling material winding Casting film control Electrical control system

Control Panel Electrostatic dust removal rewind/unwind the reel Total installed power | DL-LYJ-2QE240 2980*600*1250MM (L*W*H) Aqueous, solvent PET film (100um) 250mm 220mm 0.001mm ±(1um+2%belt thickness) 0.1um Cylinder comma-shaped scraper 0.01-2 (m/min) 5-400μm (static achievable over 1200um) 0-3500μm 200-50000 2m 3 stages bottom heating + hot air circulation RT-100℃ Adjustable (Control ±0.1℃) Maximum roll diameter 200 0.02-2m/min continuous winding Dual servo control, adjustable tension Siemens PLC, programmable control 10-inch color LCD touch screen 4 sets 3 inch air-expansion shaft around 2.6Kw |