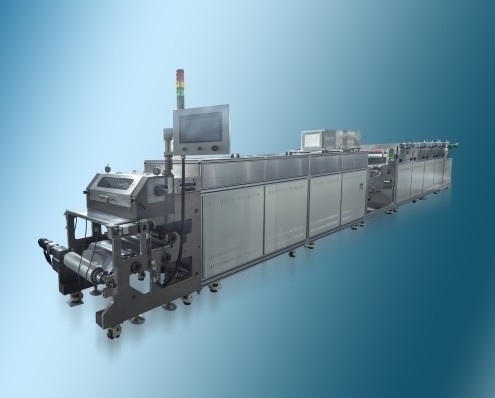

DL-LYJ-8MG350HA tape casting machine is our advanced product, suitable for the highest production requirements. With advanced tool adjustment, servo tension control, quick alignment correction, and an efficient drying system, it is well-suited for the production of ceramic tapes ranging from 20 to 200 micrometers. The entire process, from feeding to collecting the green bodies, is highly automated.

DL-LYJ-8MG350HA tape casting machine is our advanced product, suitable for the highest production requirements. With advanced tool adjustment, servo tension control, quick alignment correction, and an efficient drying system, it is well-suited for the production of ceramic tapes ranging from 20 to 200 micrometers. The entire process, from feeding to collecting the green bodies, is highly automated.

Equipment model Equipment Specifications Cutting tape material Casting width Casting speed Scraper height Strip thickness Tool adjustment accuracy Tool adjustment control Thickness accuracy Dry area

Automatic feeding system

Liquid level height Ceramic tape edge trimming and slitting Electrostatic dust removal Tension control

Operating Voltage Starting power Operating power feeding pressure method | DL-LYJ-8MG350HA 12800*1150*1450MM (L*W*H) PET film (100um) 350mm 0.05 - 6.0 (m/min) 5 - 4500um 20 - 200um 0.001mm Motor plus ball screw ±(1um+2%belt thickness) Area 1 ---4 stages bottom heating (max temp 120℃) Area 2 ---Drying box length 4 meters, divided into 20 groups of air heating modules, each group independently controls temperature, heating range: RT-300℃ Fully automatic feeding, Siemens PID control flow rate and precise ±0.1mm 0.0 - 40.0mm Carbide steel insert Static elimination rod The servo motor controls the tension, baseband operates without fluctuations 380V 50/60HZ ≈40KW ≈20KW Nitrogen pressurization |